Blog

What is a good job to make precise and bright enough cross line indication onto various garment cloths? It is not easy to reach with any prior cross line drawing or printing work, but making even better job to apply a highly intense beam emitted tool of a 650nm red cross line laser module. It always gets constant electric power source supply and applies both import laser diode and qualified optic lens inside a durable housing tube. Whenever it is properly installed or integrated into those of garment processing device or equipment, not limited by manual labor force input or professional skills, this direct diode emission made red cross laser alignment enables highly bright red laser light source generation, which is suitable for various garment fabrics such as cotton, linen, silk, and synthetic fibers, with no risk of damage.

When 660nm red cross line laser module gets constant electric power source from a 5V, 9V or 12V 1000mA AC/DC adapter, unlike spending extra time on prior cross line drawing or printing work, it is working well with wide range output power of 5mW to 100mW and high power up to 150mW to 500mW. The 660nm red light is a cold light source, irradiating fabric without high temperatures or burn marks. Usually it applies a durable anodized aluminum alloy housing tube with 16mm, 18.9mm and 26mm diameter tube design, thus red cross laser alignment supports wide range output power of 5mW to 500mW. Whenever it gets superior nice heat dissipation, under operation with wide operating temperature and other mechanical calibration or moving, it still maintains ultra stable red vertical and horizontal lines generation in the lighting and fabric reflection environments of garment workshops. The crosshairs are distinct, allowing workers to see them without getting close, improving work efficiency.

Being made with a qualified glass coated lens and glass window in front of beam aperture, 660nm red cross line laser module keeps work with stable and clear red cross line projection under moisture, dust, rain, water or fog etc. After its correction use of output power and optic lens fan angle, after proper adjustment of both of cross line thickness and emitting direction, it can accurately control millimeter-level dimensional deviations, solving the pain points of asymmetrical garment parts and large cutting errors, improving quality control. Usually 660nm red cross laser alignment can be directly installed on various garment processing equipment, such as cutting tables, sewing machines, and ironing tables. Featured by low power consumption and durable structure, it is suitable for long term operation in the workshop. It is also dustproof and resistant to slight vibration, which can adapt to the high-frequency operation conditions in the garment workshop and has extremely low maintenance costs.

Applications in garment processing works:

Fabric Cutting Marking: 660nm red cross line laser module projects crosshair reference lines onto cutting equipment to mark the origin point and horizontal and vertical cutting boundaries of the cut pieces, unifying the cutting dimensions of multi-layer fabrics and avoiding inconsistent piece sizes.

Layout Alignment Calibration: Assists in fabric layout, accurately positioning the reference points for printed and embroidered patterns, ensuring that the printed/embroidered positions are centered, symmetrical, and conform to the design pattern.

Component Sewing Alignment: 660nm red cross laser alignment is used in flatbed sewing machines, lathes, and other equipment to mark the reference lines for garment piece splicing, adapting to the precise sewing of components such as collars, cuffs, and pockets, ensuring left-right symmetry and uniform dimensions.

Template Processing and Positioning: Used in conjunction with garment template machines, the crosshair marks the contact position between the template openings and the fabric, improving template cutting accuracy and the standardization of subsequent sewing.

Ironing and Shaping Assistance: Baseline alignment laser lines are marked on the ironing table to assist in ironing and shaping collars, plackets, and trouser creases, ensuring straight lines and a uniform, neat pattern.

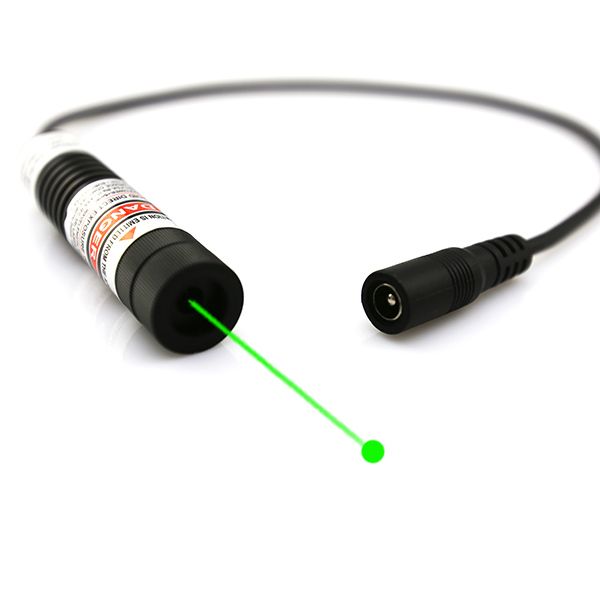

Cooperated with advanced 515nm green laser diode tech and a qualified glass coated lens inside a durable metal housing tube, it is manufacturing into a professional cross line measuring device, such as a 515nm green cross line laser module. It generates the most complex laser light source in type of two perpendicular green lines with different dimension. In multiple industrial and high tech precise cross line alignment work filed, owing to its ultra compact and durable structure design, this green cross laser alignment is always assisting with other machine or device, providing users easy, quick reaching and noncontact green cross line source for all machinery processing fields conveniently.

Inside the durable anodized aluminum alloy housing tube, 515nm green cross line laser module applies a qualified 515nm green laser diode and glass coated lens with 10, 15 and 110 degree fan angles. It projects highly sensitive color green light to the human eye, thus the projected green vertical and horizontal lines are clearly observed at several miles far away. Cooperated with low laser beam divergence and adjustable focus optic lens design in front of laser beam aperture, this green cross laser alignment enables adjusted cross line thickness so as to be adapted to different scenarios. The green laser beam thickness can be available at a distance of 3 meters of less than 2mm, allowing for adjustments to the crosshair thickness so as to improve measurement accuracy.

When 515nm green cross line laser module applies a durable anodized aluminum alloy shell, configured with a metal heat sink cooling system and import laser diode, it boasts strong thermal conductivity and heat dissipation, providing 10 times the heat dissipation of ordinary lasers, supporting long term continuous operation. When it is designed with different operating voltage of 5V, 9V and 12V 1000mA AC/DC adapter, owing to its acceptation of wide range electric current of 100V to 240V, green cross laser alignment is suitable for various power supply scenarios in industrial and scientific research. Every time it gets high brightness green laser light emission under natural light, it can make ultra clear and precise green vertical and horizontal lines generation for both of indoor and outdoor working occasions. Its wavelength has high absorption rates in materials such as copper, ceramics, and polymers, making it suitable for processing special materials.

Being made with ultra compact size tube design, together with electric wires extension for both of 515nm green cross line laser module and DC power supply, it is easy to install on various equipment. It also accepts customized design so as to meet the personalized needs of various fields such as industry, medical care, and scientific research. Within the lowest energy and time consumption, it provides factory workers and engineers for all precise cross line measuring works conveniently.

General applications:

Industrial Processing: In machining, 515nm green cross line laser module provides crosshair reference lines for lathes, milling machines, and other equipment, assisting in workpiece clamping and positioning. In laser cutting and metal welding, it marks cutting paths and weld seams, even enabling precise positioning in highly reflective copper welding. In screen printing and the textile industry, it can also assist in calibrating printing plates and fabrics, ensuring accurate pattern printing and cutting positions.

Construction: It can be used in scenarios such as wall tile laying and ceiling joist installation. The crosshairs can simultaneously calibrate horizontal and vertical directions, ensuring the squareness and flatness of the construction. It is also compatible with laser surveying instruments, assisting in solving leveling and squareness problems during construction.

Medical and Scientific Research: In the medical field, 515nm green cross laser alignment can assist in the positioning of laser treatment equipment, such as marking treatment areas in skin removal and minor eye surgeries, reducing damage to healthy tissues. In scientific research experiments, such as laser interferometry and material surface inspection, it provides a stable crosshair reference, ensuring accurate experimental data.

Other applications: High-power green alignment lasers can be used for military aiming and positioning, which are also compatible with laser rangefinders and other equipment, facilitating long-distance accurate ranging and positioning.

Based on the advanced use of a 515nm green laser diode tech and a qualified optic lens inside a highly durable metal housing tube, not simply relying on any prior line drawing or printing work, it would be a much better solution for professionals and engineers to apply a direct diode emission made tool of a 515nm green laser line generator. Basically it gets constant electric power source supply and proper integration or installation with those of machine or equipment, it enables long term lasted and high stability green line projection at various work distances conveniently.

When 515nm green laser line generator gets constant electric power source from an AC/DC adapter, unlike the simple manual line drawing or printing work, it enables constant green laser light emission from an import 515nm green laser diode. When it gets special use of a metal heat sink cooling system inside a durable anodized aluminum alloy housing tube, it just gets superior nice heat dissipation and thermal conductivity, thus it assures ultra high level of stability green laser line projection within daily operating time of 10 hours. 515nm green line laser alignment projects a highly straight green reference line, replacing manual scribing, marking reference surfaces/alignment lines for processing, assembly, and inspection, adapting to automated operations.

Being made with a qualified glass coated lens within 10 to 110 degree fan angles and adjustable focus optic lens design inside a high duration anodized aluminum alloy housing tube, 515nm green laser line generator emits high linear quality and highly straight green reference line within 0.5 meter to 6 meters length. It can assist in workpiece plane calibration, robotic arm motion trajectory positioning, and workpiece posture alignment on production lines. In addition, when green line laser alignment gets proper screw of beam aperture, the powerful and intense green laser light can be immediately converted into an increasing accuracy and brightness green line projection at greater distance of 25 meters. It can quickly identify workpiece surface unevenness and gap deviations, assisting vision inspection systems in interpretation.

Applications:

Industrial: 3C assembly alignment, sheet metal cutting reference, automotive body welding line guidance, machine tool guideway calibration;

Medical: Orthopedic surgical positioning alignment, medical aesthetic treatment area marking, dental orthodontic occlusion reference;

Research: 515nm green alignment laser is applied for optical path calibration lines, material deformation trajectory marking, experimental platform flatness detection.

When users are in need of ultra clear and fine line guidance for material sorting and alignment works, not workable at all to only rely on prior manual or mechanical line aligning works, it would be a better solution to apply a highly intense beam emitted tool of a 445nm blue laser line generator. Being made with an import 445nm blue laser diode and a qualified optic lens inside a durable and ultra compact structure tube, only after its connects with DC power supply, blue line laser forms into high contrast visual light emission and more accurate recognition blue reference line projection for multiple industrial material processing works.

Usually 445nm blue laser line generator gets constant electric power source from an AC/DC adapter, without spending extra time on prior alkaline battery change. Being made with an import 445nm blue laser diode within 50mW to 100mW and high power up to 150mW to 500mW, the short wavelength blue laser light forms high contrast onto processing materials, such as black plastic, dark metal, colored packaging, transparent glass. Even though blue line laser module is pointing under strong lighting environment of a production line, the straight line remains sharp and clearly visible, reducing the recognition error of the machine vision system and improving sorting/alignment accuracy to ±0.1mm, meeting the needs of precision material handling.

Being made with ultra compact size tube design, equipped with APC, ACC driving circuit board and a metal heat sink cooling system inside, 445nm blue laser line generator enables the power stability of ≤±3% after 24 hours of continuous operation, eliminating problems such as uneven line brightness and misalignment. The adoption of a durable anodized aluminum alloy housing tube gets superior nice thermal conductivity, which can adapt to industrial environments of -20℃-60℃ and relative humidity ≤90%, matching the production rhythm of 24-hour continuous sorting/alignment on the assembly line. After proper use of output power and optic lens fan angle, blue alignment laser can easily installed or integrated on existing production lines, sorting machines, and stacking equipment without large-scale modifications to the equipment structure. Installation and debugging only take 1-2 hours, quickly adapting to enterprise equipment upgrade needs and reducing modification investment.

General applications in material sorting and alignment:

1. Electronic Components: 445nm blue laser line generator is suitable for sorting small electronic components such as capacitors, resistors, and chips (e.g., screening by pin length and package size), and aligning PCB boards and electronic connectors in production line conveyors, ensuring the accuracy of subsequent soldering and assembly processes and reducing the defect rate of finished electronic products.

2. Packaging and Printing: highly straight blue alignment laser line can be used for sorting packaging (e.g., cartons and plastic boxes) (e.g., screening by size and printed pattern integrity), and aligning printed paper and film at the printing press feed end, avoiding printing misalignment and packaging seal deviation, suitable for mass production of food packaging and daily necessities packaging.

3. Automotive Parts: Sorting of small automotive components (such as bolts, washers, and plastic clips) (e.g., sorting by specifications and appearance defects), and alignment of automotive glass and door trim panels on assembly lines to ensure component assembly accuracy and improve automotive production efficiency.

4. Logistics and Warehousing: blue line laser module is used for sorting of express parcels and e-commerce goods (e.g., sorting by parcel size and destination label alignment), and alignment of goods during warehouse racking and pallet loading to reduce stacking misalignment, transportation damage, and improve warehousing and logistics turnover efficiency.

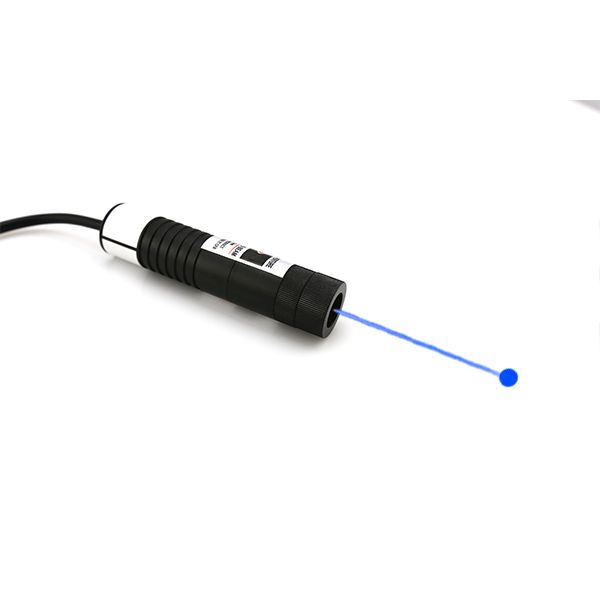

Whenever advanced 445nm blue laser diode tech is applied for the creation of a dot measuring tool, equipped with a qualified glass coated lens, laser tech engineer has designed and manufactured into a professional dot measuring device, such as a 445nm blue laser diode module. It keeps work with high blue light purity and strong directivity. Being made with basic thermal emitting system inside a durable metal housing tube, connected with constant electric power source, this direct diode emission made blue dot laser alignment enables highly focused blue laser light emission, highly efficient conversion of increasing accuracy and brightness blue dot projection at long extending distance conveniently.

Basically 445nm blue laser diode module gets constant electric power source supply from an AC/DC adapter. Compared to formal alkaline battery power source, it makes quick response blue laser light and blue dot projection from beam aperture. Employed by an import 445nm blue laser diode within 50mW to 100mW and high power up to 150mW to 500mW and basic metal heat sink cooling system inside a durable anodized aluminum alloy housing tube, blue dot laser gets sufficient space leaving for tube heat dissipation and increasing stability blue dot projection in continuous use. Usually blue dot projection bears wide range operating temperature of -10℃~60℃, unaffected by increasing temperature and serious electric current impact as well.

Compared with formal 473nm blue DPSS laser system, 445nm blue laser diode module keeps work with intense and powerful blue laser light source generation directly from an import 445nm blue laser diode, thus it can be designed with ultra compact size tube diameter design of 16mm, 18.9mm and 26mm for different output power range. Owing to its special use of APC, ACC intelligent feedback control electric current. Whatever output power it is selected, this blue dot laser alignment keeps work with good stability, easy integration and noncontact blue laser light source and blue dot generation onto any vertical or horizontal surface. Owing to its shorter wavelength than formally used green or red lasers, the projected blue laser light has high photon energy, better absorption rate for some materials (such as metals and plastics), and higher processing efficiency. The visible blue alignment laser light band offers strong visualization, making debugging and operation more convenient.

General applications in multiple fields:

• Industrial Processing: Metal/plastic micro-engraving, thin film cutting, PCB marking, and light source for 3D printing (SLA photopolymerization).

• Scientific Research and Testing: Fluorescence excitation, spectral analysis, biomedicine (cell irradiation, photodynamic therapy assistance).

• Consumer Electronics and Displays: Laser pointing, stage lighting effects, VR/AR device positioning sensing, and laser keyboard projection.

• Security and Surveying: LiDAR (short-range ranging), beam detection in security alarm systems.

What is an efficient job for users to make ultra clear and precise dot indication at different work distances? When factory workers and engineers are looking for an easy operating and highly precise dot measuring solution, instead of the use of a simple green laser pointer or other manual dot projecting tool, it is becoming a much better solution to operate a 532nm green laser diode module. It applies advanced 532nm green DPSS laser tech and a qualified optic lens inside a high duration housing tube. Owing to its ultra small laser beam divergence of less than 1mard and special TEM00 laser beam mode, no matter it is pointing at close or long distance, this green dot laser alignment takes the lowest time and energy consumption, and makes sure of high level of accuracy and high speed dot measurement onto multiple working surfaces conveniently.

How can 532nm green laser diode module work for mechanical processing works? Usually it is designed with durable anodized aluminum alloy housing tube with different dimension of 16mm, 18.9mm and 26mm diameter. Owing to its special use of a metal heat sink cooling system inside, in process of long term lasted dot positioning work, it maintains ultra nice heat dissipation and highly stable green laser light and green reference dot projection. Usually together with other industrial device, such as a lathe, milling machine or machining center, green dot laser alignment is projecting a precise optical reference dot on the workpiece surface. Owing to its low manual labor force input and low energy consumption, this replaces traditional manual marking or mechanical guides.

Being made with a qualified glass coated lens and adjustable focus optic lens in front of beam aperture, even though it is pointing under various harsh workshop occasions, such as dust, oil etc, 532nm green laser diode module maintains ultra high energy density and highly powerful green laser light source generation. When it makes quite easy adjustment of beam aperture part, after its immediate conversion of ultra compact size green dot alignment, 532nm green dot laser alignment is applied for wide range operating temperature of -10℃~60℃, and other harsh occasion of mechanical moving or calibration as well.

General applications in industrial mechanical processing works:

Machining Start Positioning: green alignment laser can directly mark the starting point for drilling or milling on the workpiece, eliminating manual alignment errors.

Process Reference Calibration: During multi-step machining, the laser point serves as a unified reference to ensure consistent positional accuracy between successive steps (e.g., calibrating the coaxiality of milling followed by drilling).

Tool Path Guidance: 532nm green laser diode module assists the operator or automated system in confirming the tool path, preventing tool deviation and resulting in workpiece scrap.

Cooperated with advanced 650nm red laser diode tech and a qualified glass coated lens inside a durable metal housing tube, not simply made into a laser pointer, laser tech engineer has just developed a much more practically used line measuring tool of a 650nm red line laser module. It gets major function in laser cutting, which is able to provide a visual guide for the processing boundary and pre-position the cutting path, assisting the operator in accurately aligning the workpiece, confirming the cutting range, and avoiding misaligned or offset cuts. Either it is pointing at close or long distance, within the lowest production cost and the lowest relying on manual labor force input, this accessory part of laser line generator is making easy reaching, good direction and highly precise red reference line indication for multiple cutting jobs conveniently.

Every time 650nm red line laser module gets constant electric power source supply, it can easily offer high contrast on the most cutting materials, especially metals and light-colored sheets, allowing direct visual inspection without the need for cameras or precision measuring instruments. Even novice operators can quickly determine accurate positioning. Employed by an import 650nm red laser diode within 5mW to 100mW and high power up to 150mW to 500mW, being made with metal heat sink cooing system, the real use of a red laser line generator juts gets superior nice heat dissipation, ultra stable and reliable red line projection within 8 to 10 hours per day.

Every time 650nm red line laser module gets constant electric power source supply, this glass coated lens made 650nm red line laser module projects noncontact, no damaging line indication onto different working surfaces. The laser projection avoids contact with the workpiece surface, eliminating the scratches and indentations caused by traditional mechanical alignment tools (such as rulers and fixtures). This method is particularly suitable for materials requiring high surface precision (such as mirror-finish metals and acrylic). in addition, compared with prior manual line drawing or printing work, the operation of a red laser line generator is not limited by long distance, high height and other complex working environments, which makes instant red reference line, reducing single-pass positioning time from minutes to seconds, while also reducing the scrap rate caused by positioning errors.

General applications of 650nm red line laser module in laser cutting fields:

Cutting Boundary Preview: Before the actual cut, a red straight line is projected onto the surface of the material being processed (metal, acrylic, wood, etc.), clearly marking the cutting contours (such as straight lines, curves, and hole edges), allowing the operator to visually confirm whether the cutting position is consistent with the design drawing.

Workpiece Clamping and Alignment: Using the red alignment laser line as a reference, the workpiece position on the cutting platform is quickly adjusted to ensure that key features such as the workpiece edge and hole location are precisely aligned with the cutting path. This replaces traditional ruler alignment and reduces clamping errors.

Multi-layer Material Alignment: When cutting multiple stacked materials (such as multiple layers of fabric or thin metal sheets), the red laser line generator emits ultra clear red reference line, which can penetrate the surface material to assist in aligning the positions of each layer, avoiding defective products caused by misalignment between layers.